Share to

FSOK DAS085-065 KDAS Hydraulic Piston Compact Seal

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Description

-

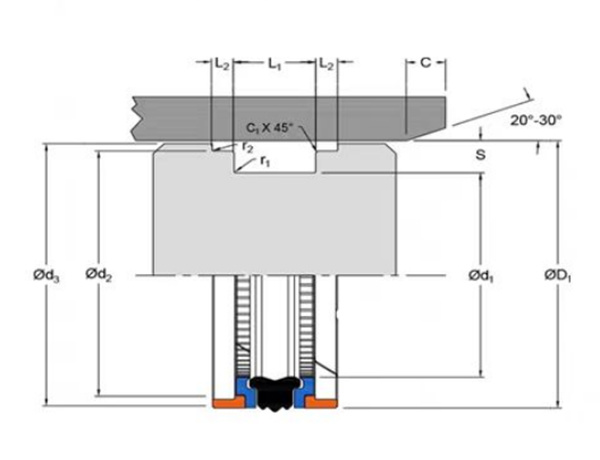

Combination piston sealing ring

Pressure: ≤ 25MPa

Speed: ≤ 0.5m/s

Temperature:- 30℃-+100℃

Media: Mineral oil, air

Structure and composition

The KDAS combination piston seal ring usually consists of the following parts:

● Main sealing ring: usually made of polyurethane (PU) or other high-performance elastic materials, responsible for the main sealing function and preventing fluid leakage.

● Support ring: usually made of wear-resistant materials such as polytetrafluoroethylene (PTFE) or nylon, used to support the main sealing ring and prevent it from deforming under high pressure.

● Guide ring: used to maintain the alignment between the piston and cylinder, reducing friction and wear.

● O-ring or elastomer: provides additional sealing and elastic support to ensure tight contact between the sealing ring and the cylinder wall.

Characteristics and advantages

● High pressure performance: The KDAS combination piston seal ring is designed for high-pressure environments and can withstand high system pressures.

● Low friction: By optimizing material and structural design, friction during piston movement is reduced, improving system efficiency.

● Wear resistance: Using wear-resistant materials to extend the service life of the sealing ring.

● Self lubrication: Some materials (such as PTFE) have self-lubricating properties, reducing dependence on lubricants.

● Strong adaptability: Suitable for various fluid media (such as hydraulic oil, water, air, etc.) and temperature ranges.

Application Fields

KDAS combination piston sealing rings are widely used in the following fields:

● Construction machinery: hydraulic systems such as excavators, bulldozers, cranes, etc.

● Industrial equipment: such as injection molding machines, die-casting machines, hydraulic presses, etc.

● Automotive industry: such as hydraulic braking systems, suspension systems, etc.

● Aerospace: Used for high-precision and high reliability hydraulic systems.

Installation and maintenance

● Installation: During installation, it is necessary to ensure that the sealing ring and the inner wall of the cylinder are clean to avoid scratching or damaging the sealing ring. Usually, specialized tools are required for installation.

● Maintenance: Regularly check the condition of the sealing ring and replace worn or aged sealing rings in a timely manner to ensure the sealing performance of the system.

Selection precautions

● Work pressure: Choose the appropriate sealing ring model based on the system's working pressure.

● Temperature range: Consider the operating temperature of the system and choose materials that are resistant to high or low temperatures.

● Media compatibility: Ensure that the sealing ring material is compatible with the system media and avoid chemical corrosion.

● Size matching: Select the appropriate sealing ring specification based on the size of the piston and cylinder.

Common problems and solutions

● Leakage: It may be due to wear or improper installation of the sealing ring, and the sealing ring needs to be inspected and replaced.

● Excessive friction: It may be due to insufficient lubrication or unsuitable sealing ring material, and the lubrication condition needs to be checked or the material needs to be replaced.

● Premature wear: may be due to harsh working conditions or improper material selection, requiring optimization of working conditions or replacement with more wear-resistant materials.

Factory

FSOK DAS085-065 KDAS Hydraulic Piston Compact Seal

Still deciding? Get samples first, Contact US !

Products Category

Keywords

Recommended similar products

ONLINE MESSAGE

Attention: Please fill in the information accurately and keep communication open. We will contact you as soon as possible